The gantry robot is widely used in automated production lines, and the grippers used for handling different products are also different. The truss manipulator introduced by the Trumen editor in this article uses a manipulator to achieve automatic handling of copper foil rolls.

This product is applied to the automatic handling of copper foil rolls using a truss manipulator. The truss manipulator grabs the roll material from the AGV and places it in a sealed cabinet. The roll material workpiece has a diameter of 1000mm and a length of 1200mm. The manipulator grabs the roll material from the AGV and places it in the sealed cabinet. The truss manipulator is compatible with manual mode and can monitor the docking position inside the sealed cabinet. It supports manual visualization docking and video recording function.

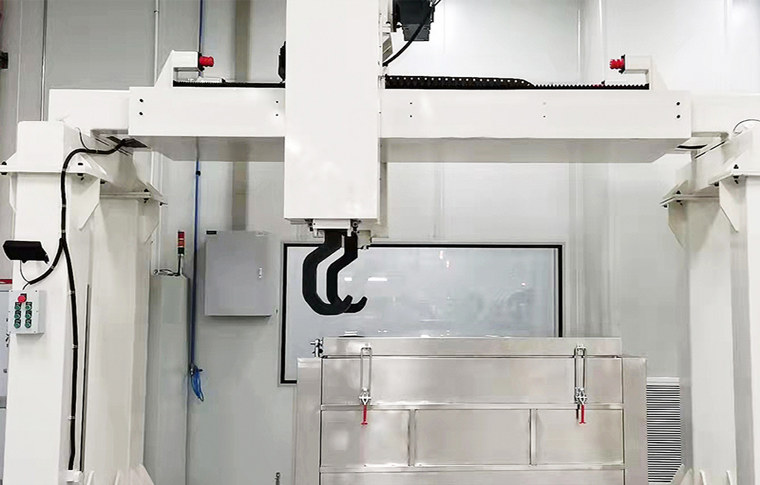

The external dimensions of the truss manipulator are 4650 × 2000 × 4350mm. The equipment is spray painted as a whole, driven by Y-axis gears and racks, and driven by Z-axis winch. Efficiency greater than 40 per hour. A human-machine recognition safety grating is installed around the perimeter of the truss manipulator equipment.

The AGV vehicle delivers the coil material to the bottom of the truss manipulator; The AGV vehicle delivers the empty sealed cabinet to the bottom of the truss manipulator, and the cylinder opens the sealed door; The truss manipulator picks up the outer 80mm section of the coil material from the AGV vehicle and sends it to the sealed cabinet.