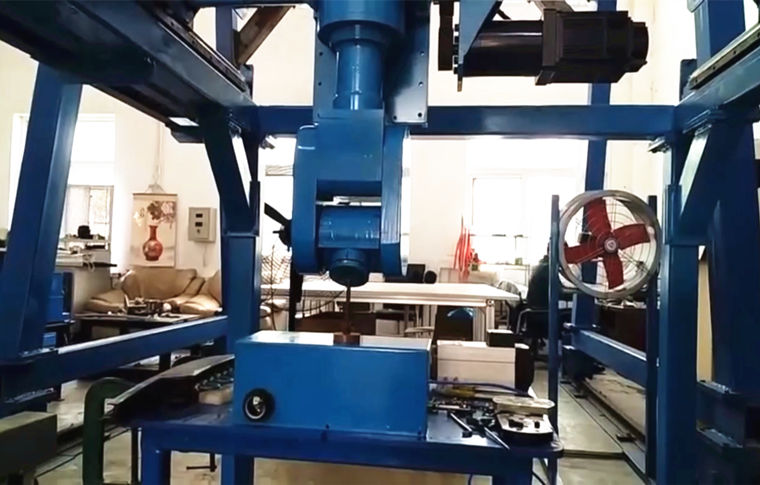

Below is an introduction to a six axis polishing robot, which can be applied to processing factory workshops for automatic polishing, thereby reducing the labor intensity of workers, improving production efficiency, and saving labor costs.

Product Introduction

The six axis polishing robot is based on Truman's years of experience in the field of industrial robots, combined with the actual needs of on-site production, using a combination of traditional machine tools and robot arms. The XYZ axis adopts a traditional coordinate walking method, which can increase the overall rigidity of the equipment and expand the working range. The 4, 5, and 6 axes use robot arm mechanisms to increase equipment flexibility, multiple degrees of freedom, and no dead corners. Moreover, the six axis polishing robotic arm is equipped with flexible polishing tools, which can adapt to different shapes and accurately control the polishing force.

Features

Adopting a top-level control system, it has powerful functions, easy operation, and high control accuracy.

Diversified control can separately control the polishing speed and improve polishing efficiency.

All components are made of high-quality international and domestic brands.

Application Industry

Automobile industry: Grinding of door welds, body welds, etc.

Sheet metal industry: Grinding of sheet metal welds

Adopting a top-level control system, it has powerful functions, easy operation, and high control accuracy.

Diversified control can separately control the polishing speed and improve polishing efficiency.

Furniture industry: Surface polishing of furniture such as wooden doors and seats.